- Good Sam Community

- Everything RV

- Technical Issues

- RV style AC attic duct work - what is it called, b...

- Subscribe to RSS Feed

- Mark Topic as New

- Mark Topic as Read

- Float this Topic for Current User

- Bookmark

- Subscribe

- Mute

- Printer Friendly Page

RV style AC attic duct work - what is it called, brand etc

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-05-2022 08:54 PM

I am trying to track down who makes them, or at least what they are called in the RV industry in attempts to buy some.

Here are pics of what I am talking about. This size has to fit through the rafters.

The ceiling registers are the older standard round turn type to adjust air flow. I know where to buy them.

This is the attic with the roof off showing the AC ducting I'm trying to locate.

The cieling air box on a older Dometic AC unit

Curved ducts come out of the air box and head down the camper through the rafters

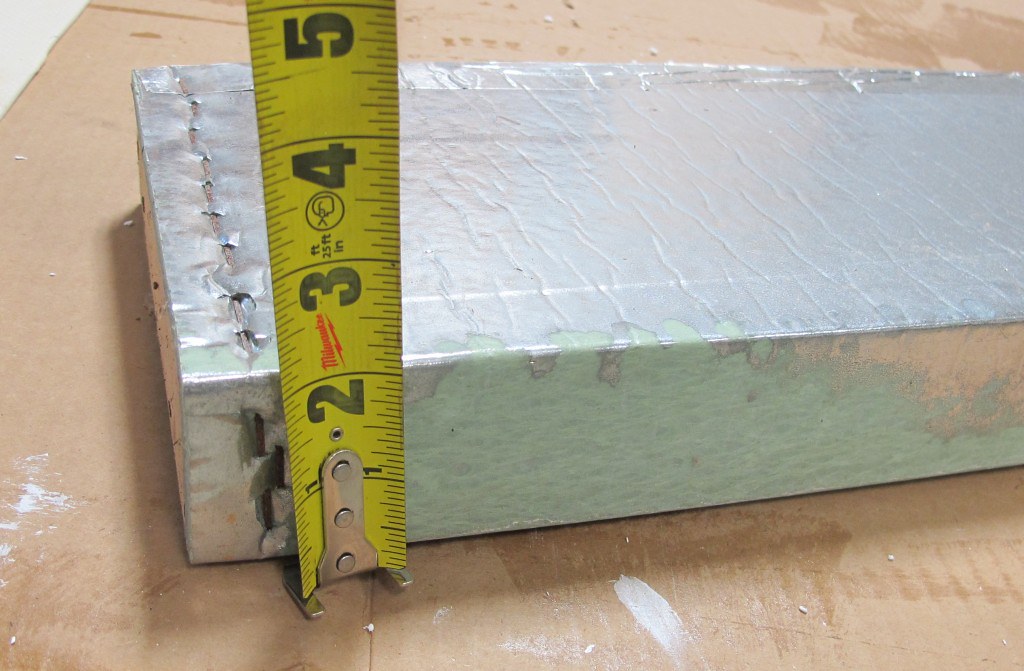

A close up of the space the duct fits through the rafter. You can see the white round ceiling register poking out of the ceiling board into the duct

Thanks for any leads on this.

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-06-2022 08:34 PM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-06-2022 06:52 PM

It is typically available at suppliers of home finishing materials, such as siding, roofing, insulation and the like.

I'd forget the big box stores such as Lowes, Home depot. They cater to the home handyman more than the tradesman.

In Canada, there is Kaycan, Gentek, Mitten Vinyl, Monarch, Royal and a bunch more. This is the best source for these kinds of materials, but only if it's the product geared towards renovation siding etc.

The V cuts in your pic work for folds, but difficult to achieve. Using and aluminum brake with gentle clamping pressure will work just fine.

RV Rebuild Website - Site launched Aug 22, 2021 - www.rv-rebuild.com

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-06-2022 06:32 PM

Thanks for your input. It all helps.

A few thoughts, it appears I may have to make up the new ducting, which is not a real problem, I can do this. The issue now is to finding the foam board or duct board in 1/4" and foil outside warped. Not sure if Jayco will sell it direct, it's an option if I can't find the board.

I did find this which could work, but I'm not sure of the thickness, yet. I have to call them, Thermopan, by the connector strips they sell, it appears it might be more like 1/8". https://thermopan.com/collections/thermo-pans

I can find it for sale on the web, https://www.supplyhouse.com/Thermopan-16050-16-x-47-5-Ultra-Fire-Resistant-Duct-Panning-Sheet

I will also check at local HVAC places.

Here are some good duct pics from a similar camper to the pics above that I am working on restoring now. I restore mainly Sunlines, but have worked on other brands too.

It is 1/4" foam board of sorts. Foil over the outside, none on the inside. It appears is was made from flat sheet, then V cut at the corners, folded and taped at the one and only seam.

This section is close to 8ft long. I have the roof all apart and can pull it out of the rafters.

The inside

You can see the angle cut corners

1/4" thick, 2" outside depth

Here is the plugged end. 2" tall x 7" 1/2" wide, wood plug in the end.

A cut out for a ceiling duct.

I had thought about possibly creating this out of metal as was suggested, but then decided this is not good in this RV attic situation. The unvented RV attic can get way over 100 deg F in the summer. The metal conducts heat well and cold too. When the AC runs, the metal hot duct is an added heat load due to the stored heat energy in the metal. And when it starts cooling, the cooling then can convect off into the attic. This appears to add high inefficiency to the system. The RV industry used foam board with foil on the outside. The outside foil I believe can help reflect heat off the duct and the foam board at least does not conduct heat or cooling as fast as metal would. Plus with the RV, foam board is mostly likely cheaper, lighter and easier to work with = $$$ saved.

I found 1/4" residing board at Home Depot, but you need to by 50 ft of it. It's an option, just there will be a ton of waste doing 1 or 2 campers. https://www.homedepot.com/p/Owens-Corning-FOAMULAR-1-4-in-x-4-ft-x-50-ft-R-1-Fanfold-Rigid-Foam-Boar...

If anyone else has something to add on where to get the 1/4" foam board, ideally with foil on one side, it will be greatly appreciated.

Thanks

John

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-06-2022 03:33 PM

nickthehunter wrote:

Video

:R

Picture snip from video in link above.

Not practical in a RV ceiling, look how thick that material is.

Might work fine in a sticks and bricks where you have virtually unlimited space to build a duct as large as you want.

Not so much when you have a very small opening such as the webbing in the roof joist that may be not much more than 3".

As I mentioned before, you would have to find fiberglass duct with a wall thickness of no more than 1/4" if you want to have a duct of any useful inside size..

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-06-2022 10:28 AM

nickthehunter wrote:

It's called "Duct Board"

Clicky

See the problem with "Duct board" in a RV that I circled in red?

1" is the thinnest I seen on that first page of the link.

Unless you can find thinner ductboard than 1" wall it will be useless in a RV ceiling as it would only give about a 1" inside dimension.. That would be like trying to drink your coffee through a coffee stirrer (it can be done but at a cost of efficiency and not worth the hassle).

For duct board to work reasonably, it would have to be very thin, not much more than 1/4" wall which would take 1/2" of the open framing dimension the OP has to work with.

Thin ductboard also has a bad habit of sagging unless it is fully supported which is what the OP is fighting with..

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-06-2022 10:02 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-06-2022 09:57 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-06-2022 08:49 AM

Wall stack dimensions are typically 3 1/4" x 10" and in 24" lengths and you can also get different elbos and is available in galvanized steel or aluminum. Snaps together fit.

Of coarse, you will need to wrap the metal ductwork in some foam insulation to reduce sweating.

You should be able to find it at Lowes, Home Depot and Amazon..

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-06-2022 06:39 AM

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-06-2022 06:36 AM

There is a construction product called Fome-Cor. I used to use it extensively years ago when I was doing reno siding on old homes. It is a quarter inch thick foam with perforated foil on one side, kraft paper on the other. 4 feet wide by 50 feet long, and it comes in a 2 foot increment fanfold.

If you have access to an aluminum brake, like the 12' 6" one I carry on my work truck, you could cut this product to size, run it through the brake and create your own duct. One side would have an overlapping flap that gets taped together with foil or duct tape.

It would be flexible enough to sideways flex it to a trapezoid shape so it could be flexed to insert into the narrow opening of the trusses, then returned to a rectangle shape. You could further insert rigid foam blocks on each side, at the trusses, to help it retain its shape.

I know I could do this as described, but you need a brake to do the folds. The brake has to have a gradual cam lock system to put gentle pressure on the foam board, not a snap lock system which would crush it.

Just thinking out loud with this idea, I have always been one to create my own things when none are available...

RV Rebuild Website - Site launched Aug 22, 2021 - www.rv-rebuild.com

- Mark as New

- Bookmark

- Subscribe

- Mute

- Subscribe to RSS Feed

- Permalink

- Report Inappropriate Content

Oct-06-2022 05:21 AM

2007 Chevy 2500HD D/A